Forenta can offer you so many choices of laundry dry cleaning presses, and finishing equipment. Quality products built in a wide range of garment presses (laundry & dry cleaning), and other miscellaneous products including form finishers, spotting boards, puff irons and garment conveyors. All to meet the needs of the textile industry and dry cleaning laundry business.

Dry Cleaning Finishing Equipment

Dry Cleaning Presses

421/461SR/SL

Forenta utility dry cleaning scissor “S” series presses with multiple buck sizes and options to choose from.

- Available with small end to the right or to the left

- All models available with grid plate or with hot head

- Fast closing and opening of head for maximum production

- Options includes iron attachment, sleeve board, water spray, timer and hanger rack

471/481/491SN/SA

Forenta legger dry cleaning scissor “S” series presses with multiple buck sizes and options to choose from.

- New wider head and buck Forenta model 491 oversized

- All models available with grid plate or with hot head

- Fast closing and opening of head for maximum production

- Options includes iron attachment, sleeve board, water spray, timer and hanger rack

191SR

Forenta mushroom dry cleaning scissor “S” series presses, model 191SR serves as a pants topper and small utility press.

- Variable head pressure for quality finishing

- Faster operating for maximum production

- Two-hand control

- Pneumatic/electric operating system

- Options includes iron attachment, sleeve board, water spray, and timer

421/461SR-BV

Forenta self contained w/boiler utility dry cleaning scissor “S” series presses, all the features and quality of a conventional press with built-in steam and vacuum.

- External compressed air required

- Multiple buck sizes and configurations

- 12 KW boiler provides plenty of dry steam

- Options include iron attachment, sleeve board, water spray, and timer

Dry Cleaning Finishing

Puff Irons

7PS/25PS/33PS

Forenta puff irons, available as Single head (7PS), Double head (25PS) and Triple head (33PS). Five buck shapes to choose from. Option includes double pedals, fabric heads, and integrated vacuum in all models.

Spotting Boards

44SP/SPG

Forenta spotting board, available in Stainless steel or Glass top to aid in spot removal. Fabric catch is standard to hold garment while spotting. Foot pedals allow the operator to control of steam, air and vacuum.

Form Finishers

604AFS/604AFL

Forenta form finishers available in Short (604AFS) or Long Form (604AFL). Finishes jackets, coats, dresses, and sweaters. Removable mesh bag for finishing delicate garments and adjustable timer variable programs for steam, air and steam/air combination.

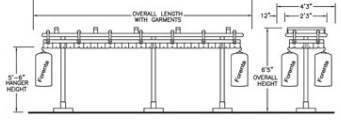

Conveyors

Forenta Saratoga line of garment conveyor systems. Conveyor include hand and foot switches for forward and reverse rotation. Special sizes and configurations available.

- Storage-Veyor (straight floor conveyor) model SA

- Eska-Veyor (Up N Down conveyor) model EV, may be floor supported and ceiling hung

- Mini-Max (double tier conveyor) model MM, short over short or short over long

- Option user friendly Auto-Trol microprocessor for automatic location of multiple orders. Can be mounted on conveyor or counter and can be used in conjunction with the hand or foot switch

Laundry Presses

A/ATA51/53/54/4224VL/VLE

Forenta VL Series large laundry garment presses tapered buck (legger/utility), available in steam or electric heated. Multiple buck sizes available, Bar closing system (safety bar activated) or Button controlled (two button activated).

- A Model A51/A53/A54/A4224 uses Control Bar Operation

- ATA Model ATA51/ATA53/ATA54/ATA4224 uses Two-Button Operation

- Fast head closing for maximum operator efficiency

- Optional features iron attachment, water spray and timer

A/ATA19VS/VSE

Forenta VS Series small laundry mushroom/topper/utility presses. Insulated Head Cover and Nickel-Plated Head Reduces Heat Loss, Saves Energy. Designed for finishing pants, shirt, blouses, and small garments. Multiple buck sizes and configurations to choose from, Bar closing system (safety bar activated) or Button controlled (two button activated). Available in steam or electric heated.

- A Model A19/A3516/A32 uses Control Bar Operation

- ATA Model AT19/ATA3516/ATA32 uses Two-Button Operation

- Fast head closing for maximum operator efficiency

- Optional features iron attachment, water spray and timer

42COU

Forenta all purpose manual utility press. Professional press finish Electrically Heated Head and Buck. Designed for public use, ideal for laundromat and coin operated facilities. No boiler or air compressor required.

- Head-up time 3-7 minutes

- Adjustable Head Pressure

- Available with coin or without coin box

- Effortless Closing Mechanism – Perfect Head Balance

Shirt Finishing Presses

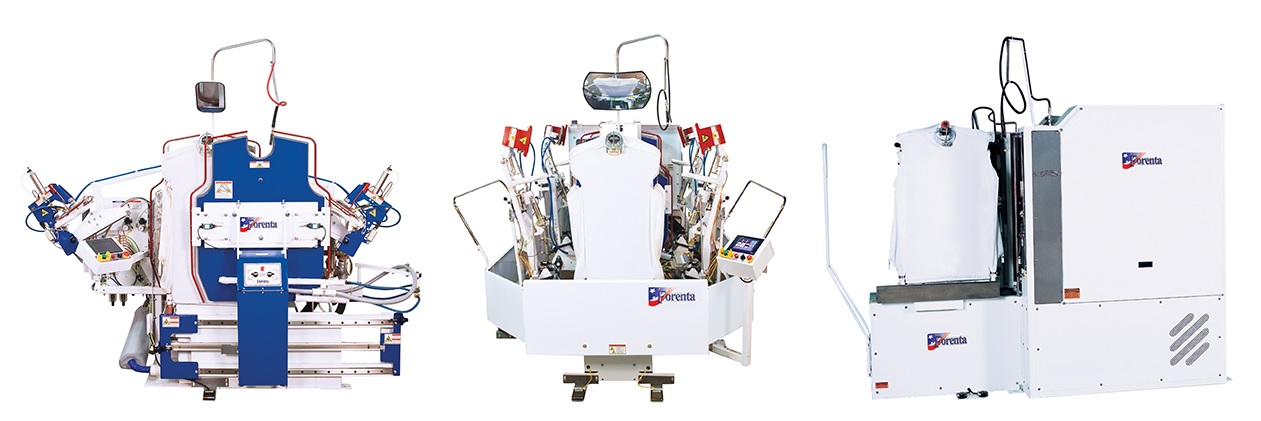

Body/Sleeve Presses

Forenta cabinet shirt finishing is the perfect system for Quality, Maximum Production, Efficiency, and Flexibility. Designed to finish a wide range of sizes and styles. Select from single buck body or double buck body shirt system based on your production requirements. If space is a concern the two piece system combination single buck body/sleeve or rotary double buck body/sleeve to reduced floor space. Forenta shirt finishing accessories available on all models, collar formers, damp box, shirt folders, touch up boards and shirt hanger.

Collar & Cuff Presses

392SCS/SCSY

Forenta collar-cuff-yoke presses designed to be used with Forenta’s Single Buck, Double Buck and Rotary Double Buck to obtain maximum production.

- Nickel Plated Heads, reduce heat loss

- Two hand control operation – easy to operate

- Water spray standard

- Model 392SCS designed to press cuffs and collar in one lay

- Model 392SCSY designed to press cuffs, collar and yoke in one lay

Sleeve Presses

905HSA/910SAB

Forenta cabinet shirt sleeve press designed to be used with Forenta’s Single Buck, Double Buck and Rotary Double Buck to obtain maximum production. Finishes both shirt and long sleeve and a wide range of shirt sizes. Buck designed with padded buck plates and inflatable air bags.

- Model 910SAB pairs with 802DBV body press

- Model 905HSA pairs with 620DBV body press

A32/A27/77SASL

Forenta Bantam 3 piece system, body press A32VB, collar-cuff-yoke press A27VCY, and air bag sleeve finisher 77SASL. Perfectly matched presses to produced a quality finished shirt. The Bantam unit 3 piece system will produce 15-20 shirts per hour. Available in either bar or two button activated closing system.

- Models available steam or electrically heated

- A models uses Control Bar Operation

- ATA models uses Two-Button Operation

- Nickel plated heads reduce heat loss and save energy

- Sleever finishes short to large size sleeves

421/461SR/SL

Forenta utility dry cleaning scissor “S” series presses with multiple buck sizes and options to choose from.

- Available with small end to the right or to the left

- All models available with grid plate or with hot head

- Fast closing and opening of head for maximum production

- Options includes iron attachment, sleeve board, water spray, timer and hanger rack

471/481/491SN/SA

Forenta legger dry cleaning scissor “S” series presses with multiple buck sizes and options to choose from.

- New wider head and buck Forenta model 491 oversized

- All models available with grid plate or with hot head

- Fast closing and opening of head for maximum production

- Options includes iron attachment, sleeve board, water spray, timer and hanger rack

191SR

Forenta mushroom dry cleaning scissor “S” series presses, model 191SR serves as a pants topper and small utility press.

- Variable head pressure for quality finishing

- Faster operating for maximum production

- Two-hand control

- Pneumatic/electric operating system

- Options includes iron attachment, sleeve board, water spray, and timer

421/461SR-BV

Forenta self contained w/boiler utility dry cleaning scissor “S” series presses, all the features and quality of a conventional press with built-in steam and vacuum.

- External compressed air required

- Multiple buck sizes and configurations

- 12 KW boiler provides plenty of dry steam

- Options include iron attachment, sleeve board, water spray, and timer

Puff Irons

7PS/25PS/33PS

Forenta puff irons, available as Single head (7PS), Double head (25PS) and Triple head (33PS). Five buck shapes to choose from. Option includes double pedals, fabric heads, and integrated vacuum in all models.

Spotting Boards

44SP/SPG

Forenta spotting board, available in Stainless steel or Glass top to aid in spot removal. Fabric catch is standard to hold garment while spotting. Foot pedals allow the operator to control of steam, air and vacuum.

Form Finishers

604AFS/604AFL

Forenta form finishers available in Short (604AFS) or Long Form (604AFL). Finishes jackets, coats, dresses, and sweaters. Removable mesh bag for finishing delicate garments and adjustable timer variable programs for steam, air and steam/air combination.

Conveyors

Forenta Saratoga line of garment conveyor systems. Conveyor include hand and foot switches for forward and reverse rotation. Special sizes and configurations available.

- Storage-Veyor (straight floor conveyor) model SA

- Eska-Veyor (Up N Down conveyor) model EV, may be floor supported and ceiling hung

- Mini-Max (double tier conveyor) model MM, short over short or short over long

- Option user friendly Auto-Trol microprocessor for automatic location of multiple orders. Can be mounted on conveyor or counter and can be used in conjunction with the hand or foot switch

A/ATA51/53/54/4224VL/VLE

Forenta VL Series large laundry garment presses tapered buck (legger/utility), available in steam or electric heated. Multiple buck sizes available, Bar closing system (safety bar activated) or Button controlled (two button activated).

- A Model A51/A53/A54/A4224 uses Control Bar Operation

- ATA Model ATA51/ATA53/ATA54/ATA4224 uses Two-Button Operation

- Fast head closing for maximum operator efficiency

- Optional features iron attachment, water spray and timer

A/ATA19VS/VSE

Forenta VS Series small laundry mushroom/topper/utility presses. Insulated Head Cover and Nickel-Plated Head Reduces Heat Loss, Saves Energy. Designed for finishing pants, shirt, blouses, and small garments. Multiple buck sizes and configurations to choose from, Bar closing system (safety bar activated) or Button controlled (two button activated). Available in steam or electric heated.

- A Model A19/A3516/A32 uses Control Bar Operation

- ATA Model AT19/ATA3516/ATA32 uses Two-Button Operation

- Fast head closing for maximum operator efficiency

- Optional features iron attachment, water spray and timer

42COU

Forenta all purpose manual utility press. Professional press finish Electrically Heated Head and Buck. Designed for public use, ideal for laundromat and coin operated facilities. No boiler or air compressor required.

- Head-up time 3-7 minutes

- Adjustable Head Pressure

- Available with coin or without coin box

- Effortless Closing Mechanism – Perfect Head Balance

Body/Sleeve Presses

Forenta cabinet shirt finishing is the perfect system for Quality, Maximum Production, Efficiency, and Flexibility. Designed to finish a wide range of sizes and styles. Select from single buck body or double buck body shirt system based on your production requirements. If space is a concern the two piece system combination single buck body/sleeve or rotary double buck body/sleeve to reduced floor space. Forenta shirt finishing accessories available on all models, collar formers, damp box, shirt folders, touch up boards and shirt hanger.

Collar & Cuff Presses

392SCS/SCSY

Forenta collar-cuff-yoke presses designed to be used with Forenta’s Single Buck, Double Buck and Rotary Double Buck to obtain maximum production.

- Nickel Plated Heads, reduce heat loss

- Two hand control operation – easy to operate

- Water spray standard

- Model 392SCS designed to press cuffs and collar in one lay

- Model 392SCSY designed to press cuffs, collar and yoke in one lay

Sleeve Presses

905HSA/910SAB

Forenta cabinet shirt sleeve press designed to be used with Forenta’s Single Buck, Double Buck and Rotary Double Buck to obtain maximum production. Finishes both shirt and long sleeve and a wide range of shirt sizes. Buck designed with padded buck plates and inflatable air bags.

- Model 910SAB pairs with 802DBV body press

- Model 905HSA pairs with 620DBV body press

A32/A27/77SASL

Forenta Bantam 3 piece system, body press A32VB, collar-cuff-yoke press A27VCY, and air bag sleeve finisher 77SASL. Perfectly matched presses to produced a quality finished shirt. The Bantam unit 3 piece system will produce 15-20 shirts per hour. Available in either bar or two button activated closing system.

- Models available steam or electrically heated

- A models uses Control Bar Operation

- ATA models uses Two-Button Operation

- Nickel plated heads reduce heat loss and save energy

- Sleever finishes short to large size sleeves